- Collection

- 产品详情

- 产品简介

1. Introduction to the equipment

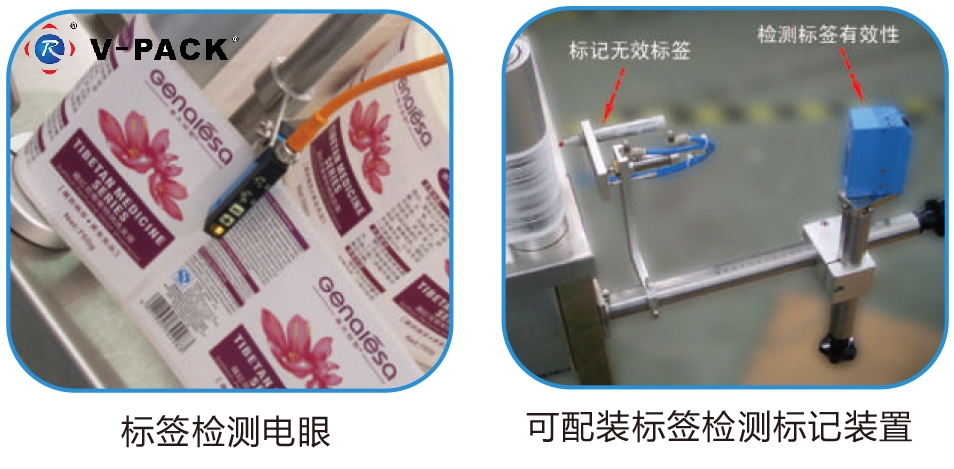

The horizontal rewinder is equipped with a standard work platform for rewinding, which is convenient for label inspection operations and can present excellent rewinding effects; it can be equipped with scanning and marking devices to detect valid labels and mark invalid barcode labels.

2. Equipment parameters

Name Horizontal luxury type

Maximum linear speed of rewinding 100m/min

Maximum outer diameter of roll 350mm

Roll width 20-200mm

Rewinding and unwinding method (adjustable) Rewinding and unwinding magnetic powder tensioner

Material coil fixing device, loading and unloading material coil is expansion shaft type tensioning

Synchronization device/information display Synchronizer, label electric eye/text control display

Alarm device Sound alarm when counting is completed, failure, etc.

Rewinding direction Biaxial unidirectional rewinding (double-shaft bidirectional rewinding is optional)

Power supply/total power AC220V 50HZ/400W

3. Appearance of equipment

Horizontal rerolling machine

Horizontal rolling machine with standard working platform to facilitate label inspection operation and excellent rolling effect; optional scanning and marking device, valid label detection, invalid barcode label, etc.

model | VPA-806 |

name | Lying luxury type |

Reroll maximum line speed | 100m/min |

The maximum outer diameter of the material roll | 350mm |

Volume width | 20-200mm |

Collection and release method (adjustable) | Volume release magnetic powder tensor |

Material coil fixing device | The loading and unloading roll is of expansion shaft tightening |

Synchronization device / information display | Synchronizer, label electric eye / text control display |

warning device | Count is completed, fault and other state sound and light alarm |

Re-volume direction | Two-axial double rewinding (optional two-axial double rewinding) |

Power / total power | AC220V 50HZ/400W |